Confirmé

- Outer Diameter (D)(φ)

- 3

- Flute Length (ℓ)(mm)

- 4.5

- Shank Diameter (d)(mm)

- 6

- Overall Length (L)(mm)

- 60

- Additional Classification

- Type

- Jours d'expédition estimés

- Tout

- Dans les 5 jours ouvrables

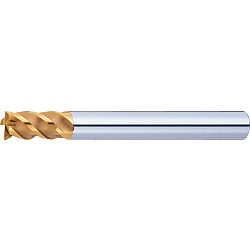

TSC series carbide multi-functional square end mill, 4-flute, 45° spiral / stub model (TSC-HEM4B3)

Schéma d’ensemble

Plus d'informations

Informations de base

The flute length type of 1.5 times the outer diameter that's capable of high-speed high feed machining

Spécifications et prix

Spécifications

| Model Number | Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure | |

| Outer Diameter D |

|||||

| TSC-HEM4B | 1 | 1.5 | 60 | 6 | 1 |

| 1.5 | 2.25 | 60 | 6 | 1 | |

| 2 | 3 | 60 | 6 | 1 | |

| 2.5 | 3.8 | 60 | 6 | 1 | |

| 3 | 4.5 | 60 | 6 | 1 | |

| 4 | 6 | 60 | 6 | 1 | |

| 5 | 7.5 | 60 | 6 | 1 | |

| 6 | 9 | 60 | 6 | 2 | |

| 8 | 12 | 75 | 8 | 2 | |

| 10 | 15 | 80 | 10 | 2 | |

| 12 | 18 | 100 | 12 | 2 | |

| 16 | 24 | 110 | 16 | 2 |

For Cutting Conditions, Refer to >>Click here.

Caractéristiques et exemples d’utilisation

Plus d'informations

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● The unique tip pocket shape allows for the cutting of grooves to be achieved with 2 flutes in parallel at the cutting depth.

● It has a stubby blade with a flute length 1.5 times greater than the blade diameter, suppressing chatter while machining bottom surfaces.

● Compared to 30° twisted square end mills, both rotation and feed capacity are more than double for higher speed machining.

La référence pièce a été confirmé