- D.E. [Distinction]

- D.I. [Distinction]

- Couleur

- Transparent (y compris couleurs non blanches)

- Bleu (translucide)

- Nombre d'âmes(âme)

- 1

- Pression de service maximum(MPa)

- Température de service(°C)

- Longueur(m)

- 20

- Type

- Jours d'expédition estimés

- Tout

- Dans les 32 jours ouvrables

TLM, Tube fluoropolymère, Dimensions en mm (TLM0302N-20)

Informations sur le produit

Fluoropolymer Tubing (PFA) Metric Size, TLM Series Details

Fluoropolymer Tubing (PFA) Metric Size, TLM Series product images

Fluoropolymer Tubing (PFA) Metric Size, TLM Series Specifications

Series Table

| Size | Metric Size | ||||||

|---|---|---|---|---|---|---|---|

| Nominal | TLM0201 | TLM0302 | TLM0425 | TLM0403 | TLM0604 | TLM0806 | TLM1075 |

| Tube Size | ø2 (diameter: 2 mm) ×; ø1 (diameter: 1 mm) | ø3 (diameter: 3 mm) × ø2 (diameter: 2 mm) | ø4 (diameter: 4 mm) × ø2.5 (diameter: 2.5 mm) | ø4 (diameter: 4 mm) × ø3 (diameter: 3 mm) | ø6 (diameter: 6 mm) × ø4 (diameter: 4 mm) | ø8 (diameter: 8 mm) × ø6 (diameter: 6 mm) | ø10 (diameter: 10 mm) × ø7.5 (diameter: 7.5 mm) |

| Outer Diameter (mm) | 2 | 3 | 4 | 4 | 6 | 8 | 10 |

| Inner Diameter (mm) | 1 | 2 | 2.5 | 3 | 4 | 6 | 7.5 |

| Size | Metric Size | |||||

|---|---|---|---|---|---|---|

| Nominal | TLM1008 | TLM1209 | TLM1210 | TLM1613 | TLM1916 | TLM2522 |

| Tube Size | ø10 (diameter: 10 mm) × ø8 (diameter: 8 mm) | ø12 (diameter: 12 mm) × ø9 (diameter: 9 mm) | ø12 (diameter: 12 mm) × ø10 (diameter: 10 mm) | ø16 (diameter: 16 mm) × ø13 (diameter: 13 mm) | ø19 (diameter: 19 mm) × ø16 (diameter: 16 mm) | ø25 (diameter: 25 mm) × ø22 (diameter: 22 mm) |

| Outer diameter (mm) | 10 | 12 | 12 | 16 | 19 | 25 |

| Inner diameter (mm) | 8 | 9 | 10 | 13 | 16 | 22 |

| Winding Length | Color | Symbol | TLM0201 | TLM0302 | TLM0425 | TLM0403 | TLM0604 | TLM0806 | TLM1075 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Roll | 10 m | Translucent | N | - | - | - | - | - | - | ● |

| 20 m | Translucent | N | ● | ● | ● | ● | ● | ● | ● | |

| Red (Translucent) | R | ● | ● | ● | ● | ● | ● | ● | ||

| Blue (Translucent) | BU | ● | ● | ● | ● | ● | ● | ● | ||

| Black (Opaque) | B | ● | ● | ● | ● | ● | ● | ● | ||

| 50 m | Translucent | N | ● | ● | ● | ● | ● | ● | ● | |

| 100 m | Translucent | N | ● | ● | ● | ● | ● | ● | ● | |

| Straight Pipe | 2 m | Translucent | N | ● | ● | ● | ● | ● | ● | ● |

| Winding Length | Color | Symbol | TLM1008 | TLM1209 | TLM1210 | TLM1613 | TLM1916 | TLM2522 | |

|---|---|---|---|---|---|---|---|---|---|

| Roll | 10 m | Translucent | N | ● | ● | ● | ● | ● | - |

| 20 m | Translucent | N | ● | ● | ● | ● | ● | ● | |

| Red (Translucent) | R | ● | ● | ● | ● | ● | ● | ||

| Blue (Translucent) | BU | ● | ● | ● | ● | ● | ● | ||

| Black (Opaque) | B | ● | ● | ● | ● | ● | ● | ||

| 50 m | Translucent | N | ● | ● | ● | ● | ● | ● | |

| 100 m | Translucent | N | ● | ● | ● | ● | ● | - | |

| Straight Pipe | 2 m | Translucent | N | ● | ● | ● | ● | ● | ● |

Specifications

| Working FluidsNote 1, Note 2, Note 3 and Applicable FittingsNote 1, Note 2, Note 3 | Fitting: Fluoropolymer fittings LQ Series | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fluids: air, water, inert gas; fittings: Single-action fittings KQ2, KQG2, KQB2; clean single-action fittings KP, KP□; Insert fittings KF, KFG2; miniature fittings M, MS (hose nipple type) | ||||||||||||||

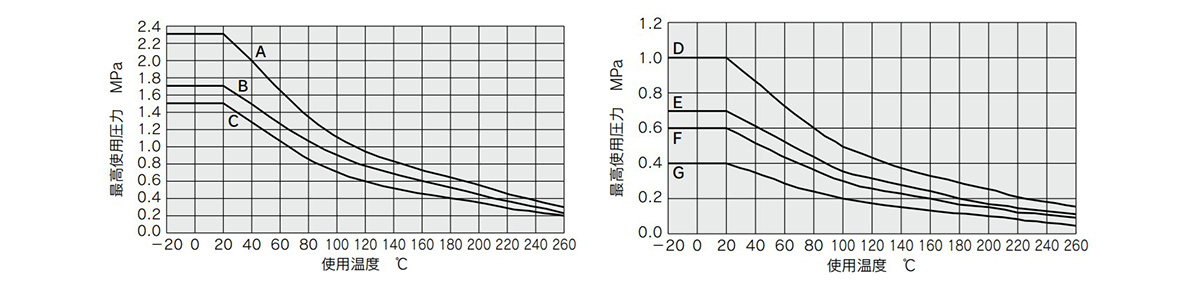

| Maximum Operating Pressure (MPa) | Please refer to the maximum operating pressure curve. | |||||||||||||

| Minimum Bending Radius mm Note 4 | Recommended Radius | 10 | 20 | 20 | 35 | 35 | 60 | 95 | 100 | 100 | 130 | 160 | 220 | 400 |

| Tube Close Bend Radius | 7 | 15 | 15 | 20 | 20 | 40 | 60 | 65 | 65 | 110 | 130 | 160 | 290 | |

| Maximum Operating Temperature | 260°C | |||||||||||||

| Material | PFA (tetrafluoroethylene, perfluoroalkoxy ethylene copolymer resin) | |||||||||||||

Note 1: Please be aware that different fittings are appropriate for different fluids.

Note 2: When using a liquid fluid, the surge pressure must be under the maximum operating pressure. If the surge pressure exceeds the maximum operating pressure, it will result in damage to the fittings and tubing. Furthermore, abnormal temperature rise caused by adiabatic compression may result in the tubing bursting.

Note 3: Do not use this product without the tubing affixed. Observe the lesser value of the maximum operating pressure between the tubing and fittings. Deterioration of materials due to extended use or exposure to high temperatures can lead to the development of leaks and other defects. Perform periodic maintenance and replace with a new product immediately when abnormalities are detected.

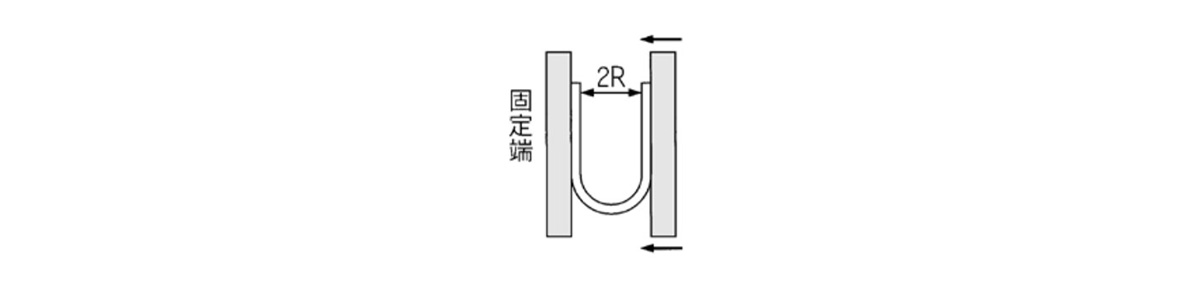

Note 4: The minimum bending radius is measured as shown in the figure below.

- *Use a tube with a radius higher than the recommended minimum bending radius.

- *The tubing may bend if used under the recommended minimum bending radius. Refer to the tube close bend radius and make sure that the tubing is not bent or flattened.

- *The tube close bend radius is not guaranteed. The value of 2R is the value measured with a flattened tube using the method shown in the figure below.

- *The minimum bending radius shown above does not apply to straight pipes (2 m).

How to measure the minimum bending radius

Bend the tubing into a U shape at a temperature of 20°C. Fix one end and close the loop gradually. Measure 2R when the deformation ratio of the tubing outer diameter at bending reaches 5%.

Maximum Operating Pressure

Maximum operating pressure curve

| Group | Model | Maximum Operating Pressure (MPa) | |||

|---|---|---|---|---|---|

| 20°C | 100°C | 200°C | 260°C | ||

| A | TLM0201 | 2.3 | 1.1 | 0.55 | 0.3 |

| B | TLM0425 | 1.7 | 0.9 | 0.45 | 0.23 |

| C | TLM0302 | 1.5 | 0.7 | 0.35 | 0.2 |

| TLM0604 | |||||

| D | TLM0403 | 1 | 0.5 | 0.25 | 0.15 |

| TLM0806 | |||||

| TLM1075 | |||||

| TLM1209 | |||||

| E | TLM1008 | 0.7 | 0.35 | 0.17 | 0.11 |

| TLM1613 | |||||

| F | TLM1210 | 0.6 | 0.3 | 0.15 | 0.1 |

| TLM1916 | |||||

| G | TLM2522 | 0.4 | 0.2 | 0.1 | 0.05 |

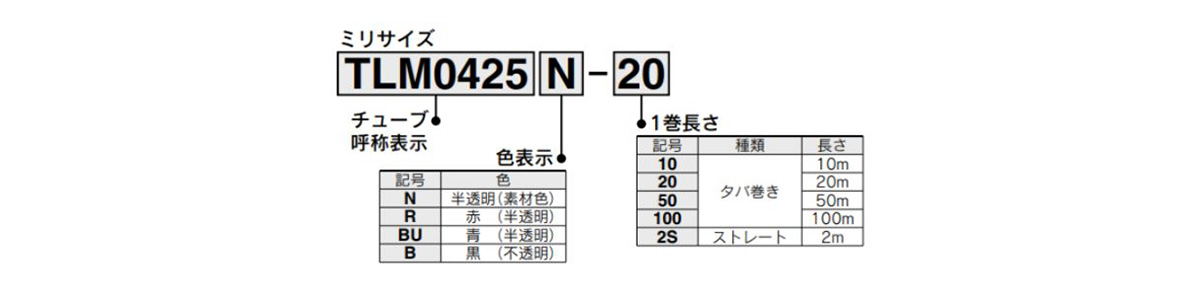

Model Number Indication Method

Example model number

Note: Tubing length will vary for each size. Please refer to the "series table."

Plus d'informations

Informations de base

Superior heat resistance: fluoropolymer tubing (PFA) metric size, TLM series.

[Features]

· Uses highly chemical-resistant fluoropolymer.

[Applications]

· Used in the manufacture of solar cells, liquid crystals, hard disk drives, and in the healthcare and food industries.

Attention

- For materials and specification details, please refer to the catalog.

- Product images may be representative images. Refer to the catalog for details.

- The last digits of the product codes indicate the length of the tubings.