- Type à commutation

- Type de connexion

- Diam. d'orifice(Ø)

- 2

- Type d'ouverture de tuyau (détails)

- Tension

- Consommation d'énergie(W)

- 2.5

- Longueur du fil de sortie(mm)

- 300

- Matériau des pièces en contact avec des liquides

- Fonctions

- Spécifications de l'embase

- Conformité CE

- Type

- Jours d'expédition estimés

- Tout

- Dans les 66 jours ouvrables

LVM20 / 200, Electrodistributeur compact 2 / 2 et 3 / 2 à commande directe pour les produits chimiques (LVM20R3-5B-Q)

Informations sur le produit

Compact Direct Operated 2/3 Port Solenoid Valve For Chemical Liquids LVM20/200 Series Specifications

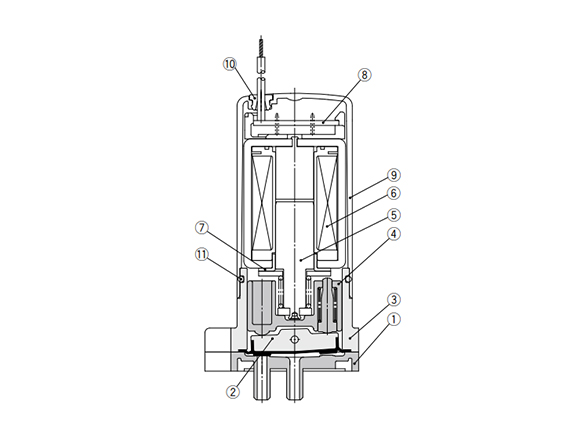

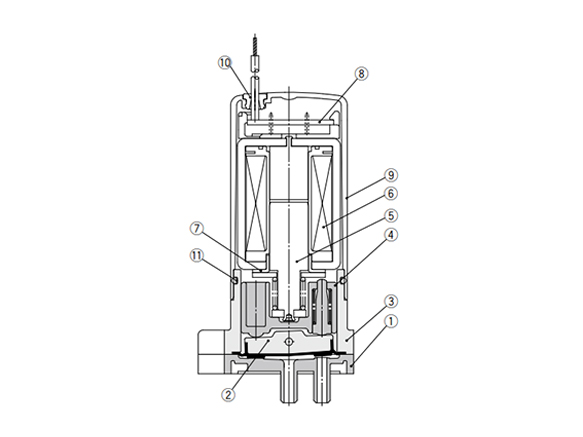

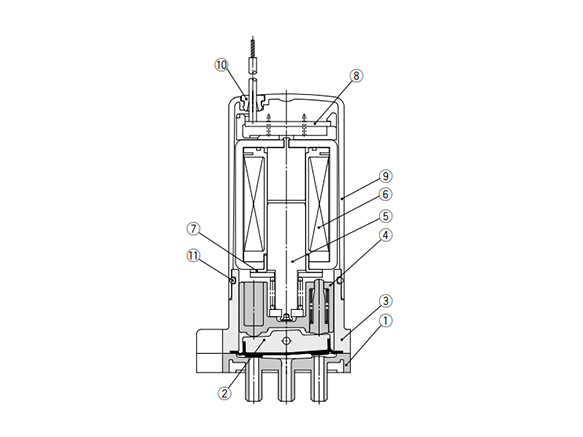

Body ported type (tubing type) external appearance

Base Mounted Type (Without Sub-Plate) external appearance

Base Mounted Type (With Sub-Plate) external appearance

| Model | Body Ported Type (Tubing Type) | Base Mounted Type | ||||||

|---|---|---|---|---|---|---|---|---|

| LVM20R1 | LVM20R2 | LVM202R | LVM20R3 | LVM20R4 | LVM205R | |||

| Valve Structure | Diaphragm type direct acting poppet (rocker type) | |||||||

| Valve Type | N.C. | N.O. | Universal | N.C. | N.O. | Universal | ||

| Number of Ports | 2 | 3 | 2 | 3 | ||||

| Fluids*1 | Air, water, deionized water (pure water), diluent, detergent | |||||||

| Operating Pressure Range | -75 kPa to 0.25 MPa | -75 kPa to 0.3 MPa | ||||||

| Orifice Diameter | 2 mm | |||||||

| Response Time*8 | 20 ms or less (with pneumatic pressure) | |||||||

| Leakage Rate | Zero for both internal and external parts (with hydraulic pressure) | |||||||

| Proof Pressure*2 | 0.38 MPa | 0.45 MPa | ||||||

| Ambient Operating Temperature*9 | 0 to 50°C | |||||||

| Operating Fluid Temperature*9 | 0°C to 50°C (no freezing) | |||||||

| Volume of Valve Chamber*3 | 84 μL | |||||||

| Mounting Orientation*4 | Free | |||||||

| Enclosure | IP40 equivalent | |||||||

| Weight | 80 g | 80 g (without sub-plate), 94 g (with sub-plate) | ||||||

| Rated Voltage | 12, 24 V DC | |||||||

| Allowable Voltage Fluctuation*5 | ±10% of rated voltage | |||||||

| Coil Insulation Type | Class B | |||||||

| Power Consumption - Current (at 24‑V rated voltage) | Standard Type | 2.5 W (0.1 A) | ||||||

| With power-saving circuit | Inrush | 4 W (0.17 A) | ||||||

| Holding | 0.6 W | |||||||

| Coil Switching Noise*6 | 60 dB | |||||||

*1: Select an appropriate material for the wetted parts according to the type of fluid to be used. Be sure to check the chemical resistance beforehand.

*2: Indicates pressures which do not cause breakage or cracks after a 1 minute airtight test.

*3: Indicates the volume of the clearance inside the volume chamber after the volume of the diaphragm has been subtracted.

*4: As the body (orifice shape) is designed to eliminate residual liquid, mounting in a vertical orientation with the coil facing upward is recommended. If liquid pooling is not an issue, it may be installed in any orientation.

*5: If response speed is considered critical, take adequate regulations to prevent voltage fluctuations on the negative side.

*6: This value is depending on the measurement conditions and the sound level may change depending on the measurement conditions.

*7: See the SMC catalog if the valve is to be energized continuously for extended periods of time.

*8: According to JIS B8419:2010

{Value at an ambient and fluid temperature of 25°C, at rated voltage, at the maximum operating pressure (air) and when the N.C. (IN) port is pressurized}

The response time may vary depending on the supply pressure, fluid quality, piping conditions, ambient temperature, etc.

*9: Note that when the diaphragm material is Kalrez, the valve changeover time becomes significantly longer at ambient and fluid temperatures of 15°C or less in comparison to at room temperature (roughly 25°C).

- *Kalrez is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

Flow Rate Characteristics

- Water: Kv 0.055 / Cv 0.065

- Air: C 0.23 / b 0.27

*Kv, Cv values conform to JIS B 2005:1995. C and b values conform to JIB B8390:2000.

Diagram / Body Ported Type

LVM20R1 diagram

LVM20R2 diagram

LVM202R diagram

Component Parts: LVM20R1, 20R2, 202R

| Number | Part Name | Material |

|---|---|---|

| 1 | Plate | PEEK |

| 2 | Diaphragm Assembly | EPDM, FKM, Kalrez |

| 3 | Body | PBT |

| 4 | Slide Bushing Assembly | PPS, SUS |

| 5 | Armature Assembly | - |

| 6 | Coil Assembly | - |

| 7 | Sleeve | SUY |

| 8 | Board assembly | - |

| 9 | Casing | PBT |

| 10 | Plug | NBR |

| 11 | O-Ring | NBR |

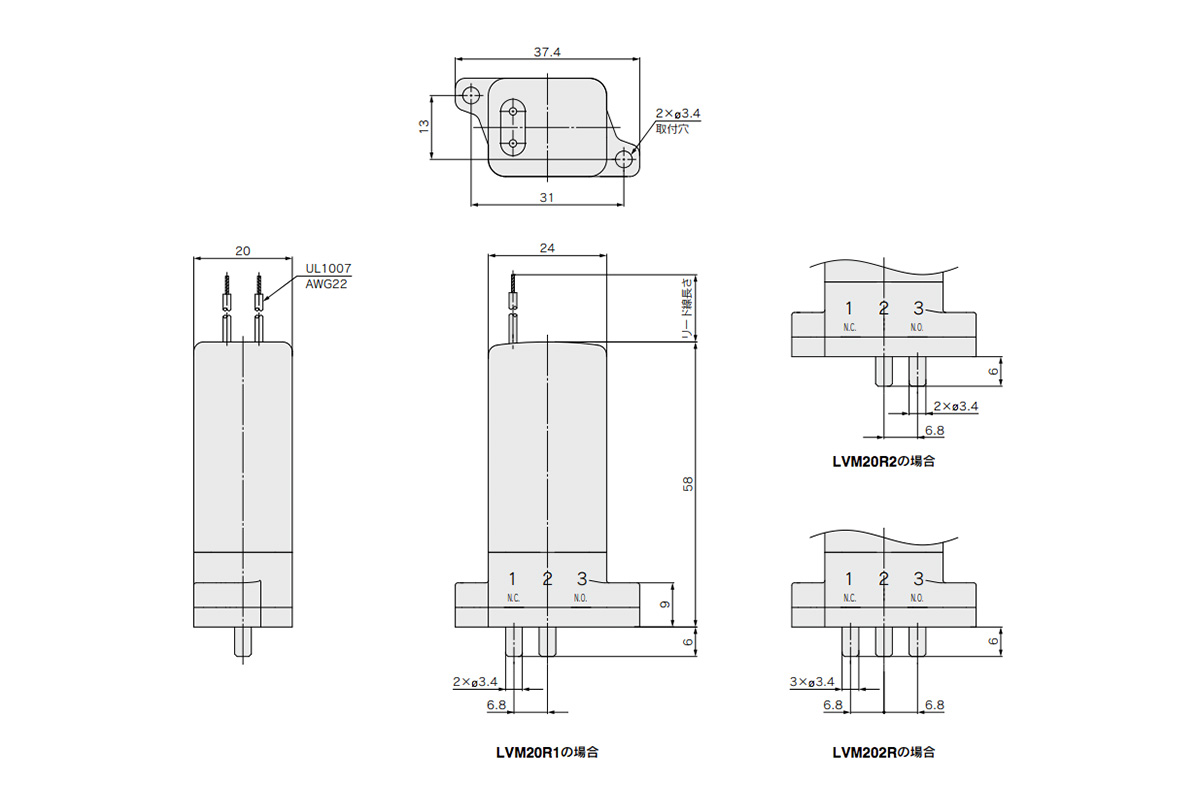

Drawing

(Units: mm)

Body Ported Type LVM20R1-□□-□ (N.C.) / LVM20R2-□□-□ (N.O.) / LVM202R-□□-□ (Universal)

LVM20R1-□□-□ (N.C.) / LVM20R2-□□-□ (N.O.) / LVM202R-□□-□ (Universal) dimensional drawing

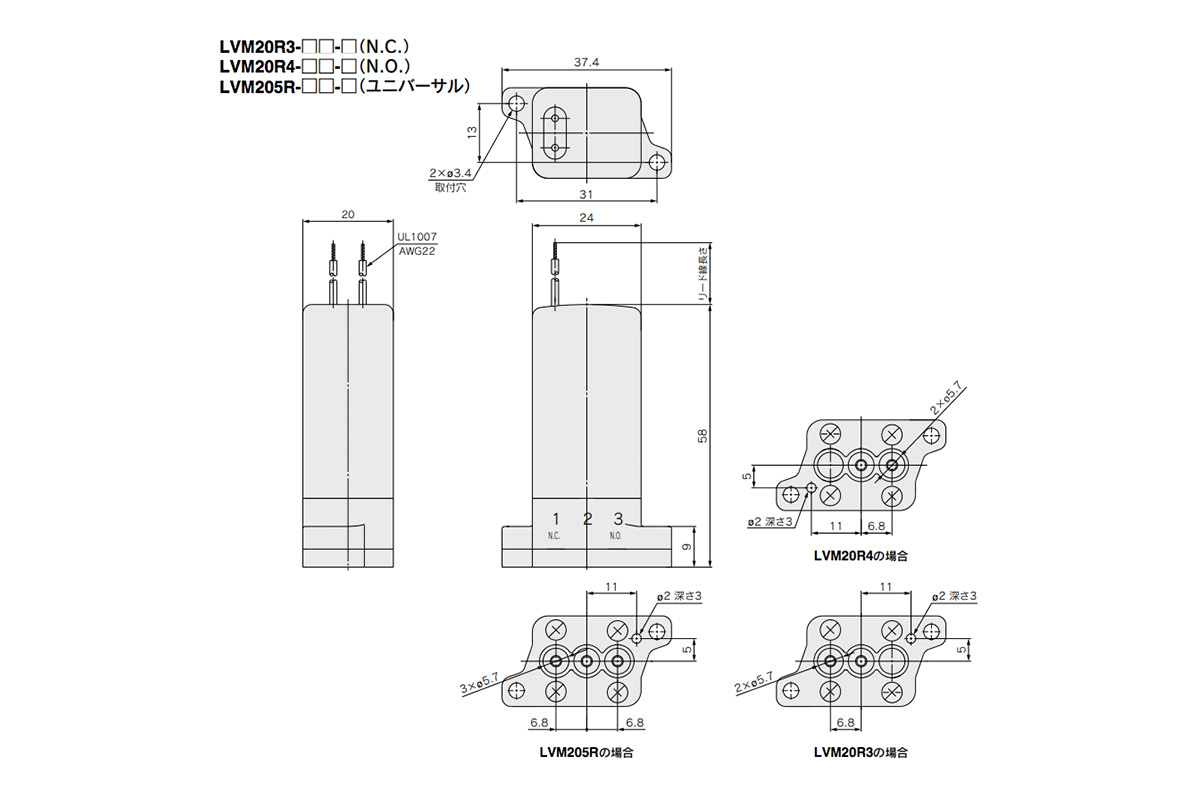

Base Mounted Type LVM20R3-□□-□ (N.C.) / LVM20R4-□□-□ (N.O.) / LVM205R-□□-□ (Universal)

LVM20R3-□□-□ (N.C.) / LVM20R4-□□-□ (N.O.) / LVM205R-□□-□ (Universal) dimensional drawing

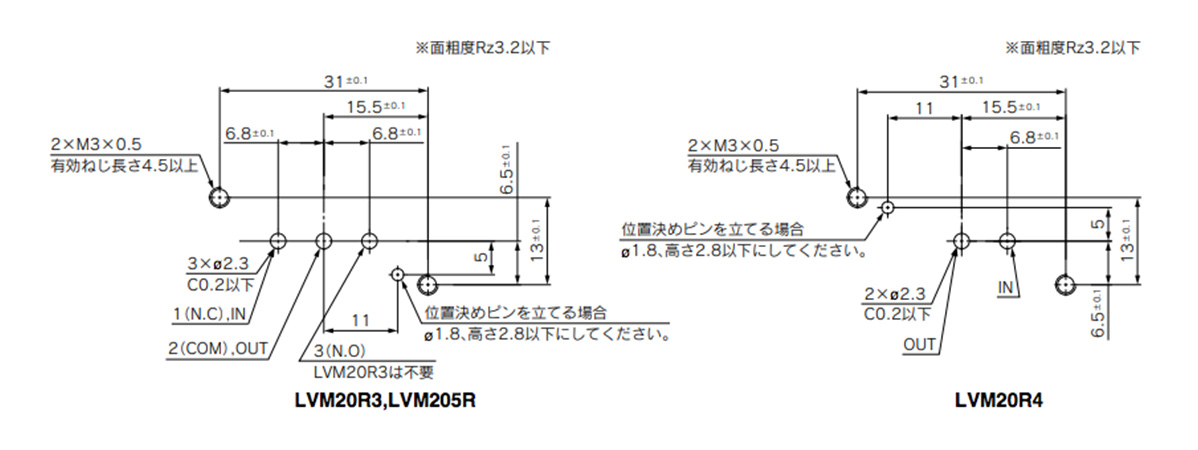

Interface Recommended Dimensions

LVM20R3-□□-□ (N.C.) / LVM20R4-□□-□ (N.O.) / LVM205R-□□-□ (Universal) image of recommended interface dimensions

*Surface roughness for LVM20R3 and LVM205R is Rz3.2 or less / Surface roughness for LVM20R4 is Rz3.2 or less

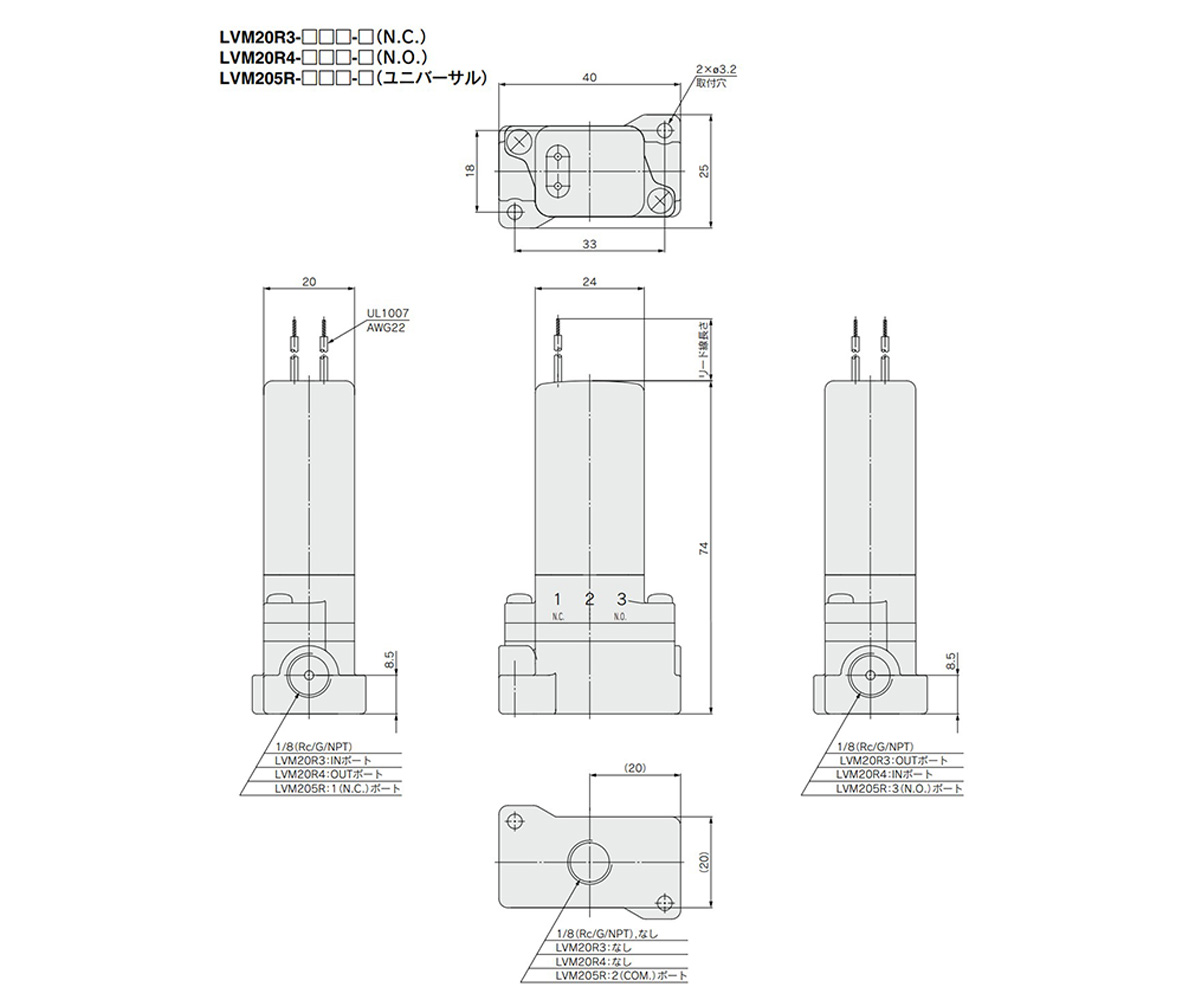

Base Mounted Type LVM20R3-□□□-□ (N.C.) / LVM20R4-□□□-□ (N.O.) / LVM205R-□□□-□ (Universal)

LVM20R3-□□□-□ (N.C.) / LVM20R4-□□□-□ (N.O.) / LVM205R-□□□-□ (universal) dimensional drawing

Precautions

- *Do not connect directly to the body via apparatus or use in applications which may adversely affect human life.

- *Confirm the specifications. Give careful consideration to the operating conditions including the application, fluid and environment. Only use within the operating ranges detailed in the SMC catalog.

- *Be sure to confirm the compatibility of the fluid used and the constituent materials of the product before use.

- *Allow sufficient space for performing maintenance and inspection.

- *Keep the supplied fluid pressure within the operating pressure range.

- *Use within the ambient operating temperature range. Make sure that no fluids or corrosive gases touch and adhere to the exterior surface of the product.

- *Take measures against static electricity as some fluids can cause static electricity.

- *As the solenoid valve allows air leakage, it cannot be used for applications such as holding pressure (including vacuums) within pressure vessels

- *Do not use as an emergency shutoff valve, etc. The solenoid valve is not designed for safety applications such as being used as a emergency shut off valve. If the valve is to be used in these types of system, other reliable safety assurance measures should be taken.

- *See the SMC catalog for information other than that detailed above.

- *Pictures are of representational models.

Plus d'informations

Informations de base

· A series of valves with a maximum change in volume of just 0.01 μL when opened or closed.

[Features]

· Body ported types and base mounted types.

· A compact direct operated 2/3 port solenoid valve for chemical liquids.

· Optional power-saving circuit.

· Space saving.

[Applications]

· Various types of analytic and testing devices.

Attention

- Les pages Web des produits qui ne disposent actuellement pas de pages individuelles sur ce site seront publiées de manière ponctuelle.

- Les images de produits peuvent être des images représentatives. Reportez-vous au catalogue du fabricant pour les détails de la forme.