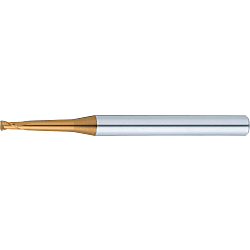

TSC series carbide tapered neck radius end mill, 2-flute / tapered neck model (TSC-REM2PB0.3-3-2-R0.05)

Cliquez sur cette image pour l'agrandir.

Cliquez sur cette image pour l'agrandir.

- Remise sur volume

Détails du produit:

Référence fabricant: TSC-REM2PB0.3-3-2-R0.05

Marque: MISUMI

Prix: 116.16 €

Délai de livraison: 5 jours

Données techniques:

Outer Diameter (D): 0.3 φ

R Size: 0.05 mm

Work Material: General Steel[◎] / Heat-Treated Steel[◎] / High-Hardness Steel ~ HRC55[○] / Acier inoxydable[○] / Fonte[○] / Aluminum Alloy[○] / Copper Alloy[○]

Flute Length (ℓ): 0.24 mm

Overall Length (L): 50 mm

- TS

- General Steel

- 2 Flutes

Référence pièce

Vous pouvez trouver ici le numéro

de référence lié au produit recherché.

TSC-REM2PB0.3-3-2-R0.05

Référence pièce

|

|---|

| TSC-REM2PB0.3-3-2-R0.05 |

| Référence pièce |

Prix unitaire standard

| Quantité minimale de commande | Remise sur volume | Outer Diameter (D) (φ) | R Size (mm) | Work Material | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Shank Diameter (d) (mm) | Length Under Neck (ℓ1) (mm) | R Precision (μm) | Additional Classification | Neck Gradient (Degree) | #6 | #7 | Figure | Under Neck Diameter d1 (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

116.16 € | 1 | Disponible | 5 jours | 0.3 | 0.05 | General Steel[◎] / Heat-Treated Steel[◎] / High-Hardness Steel ~ HRC55[○] / Acier inoxydable[○] / Fonte[○] / Aluminum Alloy[○] / Copper Alloy[○] | 0.24 | 50 | 4 | 2 | ±0.005 | Stocked Product | 3 | - | - | 1 | 0.45 |

Loading...

Spécifications

Model Number

TSC-REM2PB (Stocked Product)

| Outer Diameter D |

Neck Gradient θ1 |

Length Under Neck ℓ1 |

Radius R |

Under Neck Diameter d1 |

Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure |

| 0.2 | 1° | 1 | 0.05 | 0.22 | 0.16 | 50 | 4 | 1 |

| 2 | 0.26 | |||||||

| 3° | 1 | 0.26 | ||||||

| 2 | 0.37 | |||||||

| 5° | 1 | 0.30 | ||||||

| 2 | 0.48 | |||||||

| 0.3 | 1° | 2 | 0.05 | 0.35 | 0.24 | 50 | 4 | 1 |

| 3 | 0.38 | |||||||

| 3° | 2 | 0.45 | ||||||

| 3 | 0.55 | |||||||

| 5° | 2 | 0.54 | ||||||

| 3 | 0.72 | |||||||

| 0.4 | 1° | 3 | 0.05 0.1 | 0.48 | 0.28 | 50 | 4 | 1 |

| 4 | 0.51 | |||||||

| 3° | 3 | 0.63 | ||||||

| 4 | 0.74 | |||||||

| 5° | 3 | 0.78 | ||||||

| 4 | 0.96 | |||||||

| 0.5 | 1° | 3 | 0.05 0.1 | 0.57 | 0.32 | 50 | 4 | 1 |

| 5 | 0.64 | |||||||

| 8 | 0.74 | |||||||

| 10 | 0.81 | |||||||

| 12 | 0.88 | |||||||

| 3° | 3 | 0.71 | ||||||

| 5 | 0.92 | |||||||

| 8 | 1.23 | |||||||

| 10 | 1.44 | |||||||

| 12 | 1.65 | |||||||

| 5° | 3 | 0.85 | ||||||

| 5 | 1.20 | |||||||

| 8 | 1.72 | |||||||

| 10 | 2.07 | |||||||

| 0.8 | 1° | 5 | 0.05 0.1 0.2 | 0.92 | 0.64 | 50 | 4 | 1 |

| 8 | 1.02 | |||||||

| 3° | 5 | 1.16 | ||||||

| 8 | 1.47 | |||||||

|

1 |

1° | 6 | 0.05 0.1 0.2 0.3 | 1.14 | 0.8 | 50 | 4 | 1 |

| 10 | 1.28 | |||||||

| 15 | 1.45 | |||||||

| 20 | 1.63 | 70 | ||||||

| 25 | 1.80 | |||||||

| 30 | 1.98 | |||||||

| 35 | 2.15 | 100 | ||||||

| 3° | 6 | 1.42 | 50 | |||||

| 10 | 1.84 | |||||||

|

1.5 |

1° | 10 | 0.1 0.2 0.3 | 1.74 | 1.2 | 50 | 4 | 1 |

| 15 | 1.92 | |||||||

| 20 | 2.09 | 70 | ||||||

| 25 | 2.27 | |||||||

| 30 | 2.44 | |||||||

| 3° | 10 | 2.23 | 50 | |||||

| 15 | 2.76 | |||||||

|

2 |

1° | 15 | 0.1 0.2 0.3 0.5 | 2.38 | 1.6 | 50 | 4 | 1 |

| 20 | 2.56 | 70 | ||||||

| 25 | 2.73 | |||||||

| 30 | 2.91 | |||||||

| 40 | 3.26 | 100 | ||||||

| 50 | 3.61 | |||||||

| 3° | 15 | 3.15 | 50 | |||||

| 20 | 3.68 | 70 | ||||||

|

3 |

1° | 15 | 0.2 0.5 | 3.31 | 2.4 | 70 | 6 | 2 |

| 20 | 3.49 | |||||||

| 30 | 3.84 | |||||||

| 40 | 4.19 | 100 | ||||||

| 50 | 4.54 | |||||||

| 60 | 4.89 |

Model Number

TN-TSC-CR-EM2S (Manufactured Product)

| Outer Diameter D |

Radius R |

Neck Gradient θ1 0.5° Increment Designation |

Length Under Neck ℓ1 1 mm Increment Designation |

Under Neck Diameter d1 |

Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure |

|

1 |

0.1 0.2 0.3 | 2.5° ~ 5° | 7 ~ 19 | - | 2 | 40 | 4 | 2 |

|

1.5 |

0.1 0.2 0.3 | 2.5° ~ 3° | 8 ~ 20 | - | 3 | 40 | 4 | 2 |

| 0.1 0.2 0.3 | 3.5° ~ 5° | 8 ~ 17 | - | |||||

|

2 |

0.1 0.2 0.3 0.5 | 0.5° ~ 3° | 9 ~ 21 | - | 4 | 40 | 4 | 2 |

| 0.1 0.2 0.3 0.5 | 3.5° ~ 5° | 9 ~ 15 | - | |||||

|

3 |

0.1 0.2 0.3 0.5 | 0.5° ~ 5° | 9 ~ 15 | - | 6 | 45 | 6 | 2 |

[ ! ]When ordering manufactured products, be sure to refer to an ordering example as the points below differ from when ordering a stocked product.

(1) "TN-" is prepended to the start of the model number. (2) "S" is appended to the end of the model number. (3) The order for specifying the "radius" differs from that of stocked products.

For Cutting Conditions, Refer to >>Click here.

Plus d'informations

● It adopts a short flute length and back-tapered peripheral cutting edge for suppressing chatter.

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, yielding a longer operational life and is ideal for high speed machining / dry machining.

Informations de base

| Number of Flutes(sheet) | 2 | Model | Tapered Neck Radius | Processing Applications | Flat Surface / Side Surface / Curved Surface / Rainure / Inclined Cutting |

|---|---|---|---|---|---|

| Coating | For High Hardness (Silicone-Based) | Torsion Angle (θ) | Standard Helix (30 to 40°) |

Vous vous trouvez sur la page de TSC series carbide tapered neck radius end mill, 2-flute / tapered neck model, le numéro d'article est le suivant: TSC-REM2PB0.3-3-2-R0.05.

Veuillez trouver plus de détails concernant les particularités et les dimensions sous le numéro d'article TSC-REM2PB0.3-3-2-R0.05.

Configurer

Propriétés de base

-

Work Material

- General Steel

- Heat-Treated Steel

- High-Hardness Steel ~ HRC55

- Acier inoxydable

- Fonte

- Aluminum Alloy

- Copper Alloy

-

#6

-

#7

-

Type

- TN-TSC-CR-EM2S

- TSC-REM2PB

-

Outer Diameter (D)(φ)

-

R Size(mm)

-

Flute Length (ℓ)(mm)

-

Overall Length (L)(mm)

-

Shank Diameter (d)(mm)

-

Length Under Neck (ℓ1)(mm)

-

R Precision(μm)

-

Additional Classification

- Manufactured Product

- Stocked Product

-

Neck Gradient(Degree)

- 1

- 3

- 5

Filtrer par jours d'expédition standard

-

- Tous les articles

- 5 jours ou moins

- 8 jours ou moins

Propriétés optionnelles

- Les spécifications et les dimensions de certaines pièces peuvent ne pas être intégralement indiquées. Pour plus de détails, reportez-vous aux catalogues des fabricants .

Variantes de ce produit

| Référence pièce |

|---|

| TSC-REM2PB0.2-1-1-R0.05 |

| TSC-REM2PB0.2-3-1-R0.05 |

| TSC-REM2PB0.3-3-3-R0.05 |

| TSC-REM2PB0.4-1-3-R0.05 |

| TSC-REM2PB0.4-1-4-R0.05 |

| TSC-REM2PB0.4-1-4-R0.1 |

| Référence pièce | Prix unitaire standard | Quantité minimale de commande | Remise sur volume | Jour d'expédition standard ? | Outer Diameter (D) (φ) | R Size (mm) | Work Material | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Shank Diameter (d) (mm) | Length Under Neck (ℓ1) (mm) | R Precision (μm) | Additional Classification | Neck Gradient (Degree) | #6 | #7 | Figure | Under Neck Diameter d1 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

116.16 € | 1 | Disponible | 5 jours | 0.2 | 0.05 | Copper Alloy[◯] / Aluminum Alloy[◯] / Fonte[◯] / Acier inoxydable[◯] / High-Hardness Steel ~ HRC55[◯] / Heat-Treated Steel[◎] / General Steel[◎] | 0.16 | 50 | 4 | 1 | ±0.005 | Stocked Product | 1 | - | - | 1 | 0.22 | |

116.16 € | 1 | Disponible | 5 jours | 0.2 | 0.05 | Copper Alloy[◯] / Aluminum Alloy[◯] / Fonte[◯] / Acier inoxydable[◯] / High-Hardness Steel ~ HRC55[◯] / Heat-Treated Steel[◎] / General Steel[◎] | 0.16 | 50 | 4 | 1 | ±0.005 | Stocked Product | 3 | - | - | 1 | 0.26 | |

116.16 € | 1 | Disponible | 5 jours | 0.3 | 0.05 | Copper Alloy[◯] / Aluminum Alloy[◯] / Fonte[◯] / Acier inoxydable[◯] / High-Hardness Steel ~ HRC55[◯] / Heat-Treated Steel[◎] / General Steel[◎] | 0.24 | 50 | 4 | 3 | ±0.005 | Stocked Product | 3 | - | - | 1 | 0.55 | |

86.70 € | 1 | Disponible | 5 jours | 0.4 | 0.05 | Copper Alloy[◯] / Aluminum Alloy[◯] / Fonte[◯] / Acier inoxydable[◯] / High-Hardness Steel ~ HRC55[◯] / Heat-Treated Steel[◎] / General Steel[◎] | 0.28 | 50 | 4 | 3 | ±0.005 | Stocked Product | 1 | - | - | 1 | 0.48 | |

86.70 € | 1 | Disponible | 5 jours | 0.4 | 0.05 | Copper Alloy[◯] / Aluminum Alloy[◯] / Fonte[◯] / Acier inoxydable[◯] / High-Hardness Steel ~ HRC55[◯] / Heat-Treated Steel[◎] / General Steel[◎] | 0.28 | 50 | 4 | 4 | ±0.005 | Stocked Product | 1 | - | - | 1 | 0.51 | |

86.70 € | 1 | Disponible | 5 jours | 0.4 | 0.1 | Copper Alloy[◯] / Aluminum Alloy[◯] / Fonte[◯] / Acier inoxydable[◯] / High-Hardness Steel ~ HRC55[◯] / Heat-Treated Steel[◎] / General Steel[◎] | 0.28 | 50 | 4 | 4 | ±0.005 | Stocked Product | 1 | - | - | 1 | 0.51 |