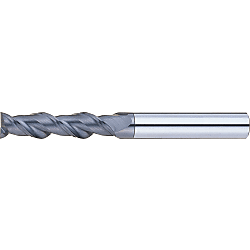

DLC Coated Carbide Square End Mill for Aluminum Machining, 2-Flute / 4D Flute Length (Long) Model

Cliquez sur cette image pour l'agrandir.

Cliquez sur cette image pour l'agrandir.

- Remise sur volume

- DLC

- Aluminum

- 2 Flutes

- L (Long)

Référence pièce

Vous pouvez trouver ici le numéro

de référence lié au produit recherché.

| Référence pièce |

Prix unitaire standard

| Quantité minimale de commande | Remise sur volume | Outer Diameter (D) (φ) | Flute Length (ℓ) (mm) | Shank Diameter (d) (mm) | Overall Length (L) (mm) | Length Under Neck (ℓ1) (mm) | Processing Applications | Additional Classification | Figure | ● Inventory Product □ Manufacturer Product | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

71.15 € | 1 | Disponible | 5 jours | 3 | 12 | 6 | 60 | - | Flat Surface / Side Surface / Rainure / Inclined Cutting | Stocked Product | 1 | ● | |

64.80 € | 1 | Disponible | 5 jours | 4 | 16 | 6 | 60 | - | Flat Surface / Side Surface / Rainure / Inclined Cutting | Stocked Product | 1 | ● | |

83.47 € | 1 | Disponible | 5 jours | 5 | 20 | 6 | 60 | - | Flat Surface / Side Surface / Rainure / Inclined Cutting | Stocked Product | 1 | ● | |

76.01 € | 1 | Disponible | 5 jours | 6 | 24 | 6 | 65 | - | Flat Surface / Side Surface / Rainure / Inclined Cutting | Stocked Product | 2 | ● | |

112.01 € | 1 | Disponible | 5 jours | 8 | 32 | 8 | 80 | - | Flat Surface / Side Surface / Rainure / Inclined Cutting | Stocked Product | 2 | ● | |

150.18 € | 1 | Disponible | 5 jours | 10 | 40 | 10 | 90 | - | Flat Surface / Side Surface / Rainure / Inclined Cutting | Stocked Product | 2 | ● | |

109.73 € | 1 | Disponible | 5 jours | 12 | 48 | 12 | 100 | - | Flat Surface / Side Surface / Rainure / Inclined Cutting | Stocked Product | 2 | ● | |

- | 1 | 8 jours | 6 | 24 | 6 | 65 | 29 ~ 47 | Flat Surface / Side Surface / Rainure / Inclined Cutting / Countersunk | Standard Neck Relief | 2 | □ | ||

- | 1 | 8 jours | 8 | 32 | 8 | 80 | 37 ~ 56 | Flat Surface / Side Surface / Rainure / Inclined Cutting / Countersunk | Standard Neck Relief | 2 | □ | ||

- | 1 | 8 jours | 10 | 40 | 10 | 90 | 45 ~ 60 | Flat Surface / Side Surface / Rainure / Inclined Cutting / Countersunk | Standard Neck Relief | 2 | □ | ||

- | 1 | 8 jours | 12 | 48 | 12 | 100 | 53 ~ 70 | Flat Surface / Side Surface / Rainure / Inclined Cutting / Countersunk | Standard Neck Relief | 2 | □ | ||

- | 1 | 7 jours | 6 | 24 | 6 | 65 | 29 ~ 47 | Flat Surface / Side Surface / Rainure / Inclined Cutting / Countersunk | Cutting Edge R Processing | 2 | □ | ||

- | 1 | 7 jours | 8 | 32 | 8 | 80 | 37 ~ 56 | Flat Surface / Side Surface / Rainure / Inclined Cutting / Countersunk | Cutting Edge R Processing | 2 | □ | ||

- | 1 | 7 jours | 10 | 40 | 10 | 90 | 45 ~ 60 | Flat Surface / Side Surface / Rainure / Inclined Cutting / Countersunk | Cutting Edge R Processing | 2 | □ | ||

- | 1 | 7 jours | 12 | 48 | 12 | 100 | 53 ~ 70 | Flat Surface / Side Surface / Rainure / Inclined Cutting / Countersunk | Cutting Edge R Processing | 2 | □ |

Loading...

Spécifications

| Model Number | Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure | |

| Outer Diameter D |

|||||

| DLC-ALHEM2L | 3 | 12 | 60 | 6 | 1 |

| 4 | 16 | 60 | 6 | 1 | |

| 5 | 20 | 60 | 6 | 1 | |

| 6 | 24 | 65 | 6 | 2 | |

| 8 | 32 | 80 | 8 | 2 | |

| 10 | 40 | 90 | 10 | 2 | |

| 12 | 48 | 100 | 12 | 2 |

For Cutting Conditions, Refer to >>Click here.

Plus d'informations

● The DLC coating has excellent wear resistance and deposition resistant properties that make it ideal for machining aluminum.

● It adopts a sharp cutting edge that prevents the built-up edge that is unique to aluminum.

Informations de base

| Work Material | Aluminum Alloy / Copper Alloy / Résine | Number of Flutes(sheet) | 2 | Model | Carré |

|---|---|---|---|---|---|

| Coating | DLC | Geometry | Sharp Corner | Torsion Angle (θ) | Powerful Helix (45° to 60°) |

| Tolerance of OD(mm) | 0 ~ -0.02 |

Configurer

Propriétés de base

-

Outer Diameter (D)(φ)

-

Flute Length (ℓ)(mm)

-

Shank Diameter (d)(mm)

-

Overall Length (L)(mm)

-

Length Under Neck (ℓ1)(mm)

-

Additional Classification

- Cutting Edge R Processing

- Standard Neck Relief

- Stocked Product

-

Type

- DLC-ALHEM2L

- SN-DLC-ALHEM2L

- SNR-DLC-ALHEM2L

-

Processing Applications

- Flat Surface

- Side Surface

- Rainure

- Inclined Cutting

- Countersunk

Filtrer par jours d'expédition standard

-

- Tous les articles

- 5 jours ou moins

- 7 jours ou moins

- 8 jours ou moins

Propriétés optionnelles

- Les spécifications et les dimensions de certaines pièces peuvent ne pas être intégralement indiquées. Pour plus de détails, reportez-vous aux catalogues des fabricants .