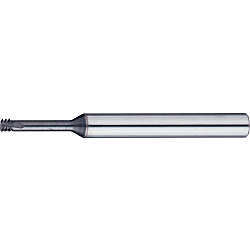

TiAlN Coated Carbide Threading Cutter, for Internal Metric Threads

Cliquez sur cette image pour l'agrandir.

Cliquez sur cette image pour l'agrandir.

- Remise sur volume

Référence pièce

Vous pouvez trouver ici le numéro

de référence lié au produit recherché.

Référence pièce

|

|---|

| MINMT-M2-0.4-4 |

| MINMT-M2-0.4-6 |

| Référence pièce |

Prix unitaire standard

| Quantité minimale de commande | Remise sur volume | Nominal | Pitch, Number of Threads (mm) | Overall Length (L) (mm) | Maximum Processing Thread Depth (mm) | Major Diameter (φ) | Shank Diameter (φ) | No. of Grooves | Length Under Neck (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

181.78 € | 1 | Disponible | 7 jours | M2 | 0.4 | 58 | 4 | 1.53 | 6 | 3 | 4.5 | |

181.78 € | 1 | Disponible | 7 jours | M2 | 0.4 | 39 | 6 | 1.53 | 3 | 3 | 6 |

Loading...

Spécifications

Model Number

MINMT

| Nominal M x P |

Maximum Machining Thread Depth |

Major Diameter D |

Overall Length L |

Length Under Neck ℓ |

Shank Diameter d |

Cutting Edge Thread No. |

No. of Grooves | |

| M1.4 | 0.3 | 4 | 1.05 | 39 | 4 | 3 | 3 | 3 |

| M1.6 | 0.35 | 4.8 | 1.2 | 39 | 5 | 3 | ||

| M2 | 0.4 | 6 | 1.55 | 39 | 6 | 3 | ||

| M2 | 0.4 | 4 | 1.55 | 58 | 4.5 | 6 | ||

| M2.2 | 0.45 | 4.5 | 1.65 | 58 | 5 | 6 | ||

| M2.5 | 0.45 | 5 | 1.95 | 58 | 5.5 | 6 | ||

| M2.5 | 0.45 | 7 | 1.95 | 58 | 7.5 | 6 | ||

| M3 | 0.5 | 6 | 2.35 | 58 | 6.5 | 6 | ||

| M3 | 0.5 | 9 | 2.35 | 58 | 9.5 | 6 | ||

| M3.5 | 0.6 | 7 | 2.75 | 58 | 7.5 | 6 | ||

| M4 | 0.7 | 8 | 3.1 | 58 | 9 | 6 | ||

| M4 | 0.7 | 12 | 3.1 | 58 | 12.5 | 6 | ||

| M5 | 0.8 | 10 | 3.8 | 58 | 12.5 | 6 | ||

| M5 | 0.8 | 15 | 3.8 | 58 | 16 | 6 | ||

| M6 | 1 | 12 | 4.65 | 58 | 14 | 6 | ||

| M6 | 1 | 18 | 4.65 | 58 | 20 | 6 | ||

| M8 | 1.25 | 16 | 5.95 | 58 | 18 | 6 | ||

| M8 | 1.25 | 24 | 5.95 | 58 | 24 | 6 | ||

| M10 | 1.5 | 20 | 7.8 | 64 | 23 | 8 | ||

| M12 | 1.75 | 24 | 9 | 73 | 26 | 10 | ||

| M16 | 2 | 32 | 11.8 | 84 | 35 | 12 | 4 | |

| M20 | 2.5 | 40 | 15 | 105 | 43 | 16 | 5 | |

Plus d'informations

● Small diameter threading is possible from M1.4 x 0.3 (pilot hole diameter Ø 1.1 mm).

● The processing time is reduced since high speed cutting is possible.

● Since the cutting length is short (3 threads), it does not apply cutting stress.

● The effective thread can be cut all the way to the corners of the blind hole.

■Misumi Threading Cutter Product CNC Program Download Services

Informations de base

| Thread Types | Métrique | Tool Material Type | Carbure | Work Material | Low-Carbon Steel (C Content of 0.25% or Less) / Medium-Carbon Steel (C Content 0.25 - 0.45%) / High-Carbon Steel (C Content Exceeding 0.45%) / Acier allié (SCM) / Stainless Steel (SUS) / Heat-Treated Steel (25 - 35 HRC) / Tool Steel (Before SKD Quenching) / Cast Steel (SC) / Fonte (FC) / Fonte ductile (FCD) / Cuivre (Cu) / Laiton (Bs) / Brass Cast Iron (BsC) / Bronze (PB) / Rolled Aluminum Material (AL) |

|---|---|---|---|---|---|

| Tap Model | Tapping Cutter | Bore Model | For Through Holes / For Blind Holes | Coating Presence | Included |

| Surface treatment | TiAlN | Number of Blade Teeth | 3 |

Configurer

Propriétés de base

-

Pitch, Number of Threads(mm)

-

Overall Length (L)(mm)

-

Maximum Processing Thread Depth(mm)

-

Major Diameter(φ)

-

Shank Diameter(φ)

-

No. of Grooves

- 3

- 4

- 5

-

Length Under Neck(mm)

-

Type

- MINMT

-

Nominal

Filtrer par jours d'expédition standard

-

- Tous les articles

- 7 jours ou moins

Propriétés optionnelles

- Les spécifications et les dimensions de certaines pièces peuvent ne pas être intégralement indiquées. Pour plus de détails, reportez-vous aux catalogues des fabricants .