Tube en fluoropolymère (FEP) gamme TH/TIH (TH1209R-20)

- En promotion jusqu’au 30/11/2024

Détails du produit:

Référence fabricant: TH1209R-20

Marque: SMC

Prix: 706.35 €

Délai de livraison: 26 jours

Données techniques:

D.E. D: 12 Ø

D.E. [Distinction]: Jusqu'à 15

D.I. d: 9 Ø

D.I. [Distinction]: Jusqu'à 9

Couleur: [Transparent (y compris couleurs non blanches)] Transparence

(i)Remarque

- Les valeurs maximales de pression de fonctionnement indiquées sont à 20°C. Voir le catalogue pour plus de détails.

- Les derniers chiffres des codes produits indiquent la longueur des tubes.

Référence pièce

Vous pouvez trouver ici le numéro

de référence lié au produit recherché.

TH1209R-20

- Données produit

- Données CAO non disponibles

Specifications Of Fluoropolymer Tubing (FEP) TH/TIH Series

Appearance of Fluoropolymer Tubing (FEP) TH/TIH Series

Color

- Translucent: N

- Red (translucent): R

- Blue (translucent): BU

- Black (translucent): B

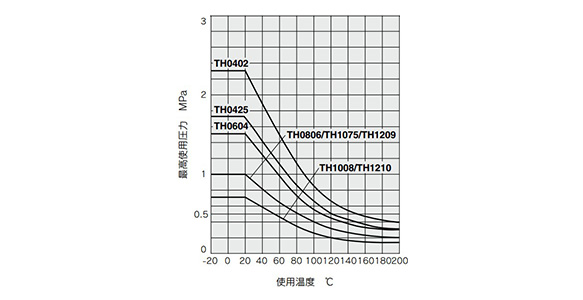

Metric Sizes TH Series

Maximum operating pressure

Note) The maximum operating pressure varies depending on the inner diameter bore size even if the outer diameter is the same.

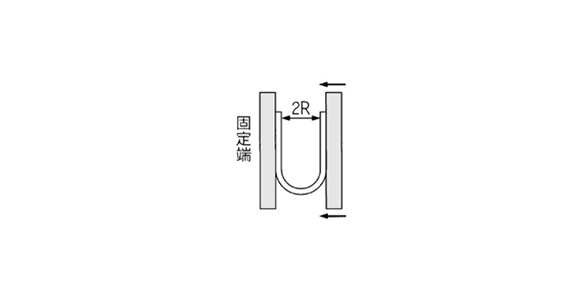

How to measure the minimum bending radius

Bend the tubing into a U shape at a temperature of 20°C. Fix one end and close the loop gradually. Measure 2R when the deformed ratio of the tubing diameter at bending reaches 5%.

| - | Metric Size | |||||||

|---|---|---|---|---|---|---|---|---|

| Nominal | TH0402 | TH0425 | TH0604 | TH0806 | TH1075 | TH1008 | TH1209 | TH1210 |

| Outer diameter mm | 4 | 4 | 6 | 8 | 10 | 10 | 12 | 12 |

| Inner diameter (mm) | 2 | 2.5 | 4 | 6 | 7.5 | 8 | 9 | 10 |

Specifications

| Fluid | Air, waterNote 1), inert gas | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Applicable fittingsNote 2) | One-touch fittings Insert fittings Fluoropolymer fittings: LQNote 3) Series Miniature fittings: M, MS Series (Hose-nipple type) | ||||||||

| Maximum operating pressure (MPa) | 20°C | 2.3 | 1.7 | 1.5 | 1 | 0.7 | 1 | 0.7 | |

| 100°C | 0.85 | 0.6 | 0.55 | 0.4 | 0.25 | 0.4 | 0.25 | ||

| 200°C | 0.4 | 0.3 | 0.3 | 0.2 | 0.1 | 0.2 | 0.1 | ||

| Refer to the maximum operating pressure curve. | |||||||||

| Minimum bending radius mmNote 4) | Recommended radius | 15 | 20 | 35 | 60 | 95 | 100 | 130 | |

| Tube close bend radius | 10 | 15 | 20 | 40 | 60 | 65 | 110 | ||

| Operating temperature | Air, inert gas: -20 to 200°C / Water: 0 to 100°C (No freezing) | ||||||||

| Material | FEP (Fluorinated Ethylene Propylene Resin) | ||||||||

Note 1) When using a liquid fluid, the surge pressure must be under the maximum operating pressure. If the surge pressure exceeds the maximum operating pressure, it will result in damage to the fittings and tubing. Furthermore, abnormal temperature rise caused by adiabatic compression may result in the tubing bursting.

Note 2) Do not use in locations where the FEP tubing will move. Be sure to operate under the maximum operating pressure and maximum operating temperature conditions using the lower maximum operating specification of either the tubing or fittings. A material change over a long duration or due to high temperature may cause leakage. Perform periodic maintenance and replace with a new product immediately when abnormalities are detected. When the insert and miniature fittings are used over extended periods of time, it may cause leakage due to age-related material deterioration. In such a case, apply additional tightening to the tube connection part. If leakage still occurs after applying additional tightening, replace the fitting with a new product. For other precautions, refer to "Fittings & Tubing Precautions" in the catalog. When using the fluoropolymer fittings, refer to the precautions in the catalog. Select the size after confirming the outer diameter and inner diameter.

Note 3) TH0402, TH0425, TH1075 and TH1209 are not available because of different internal diameters.

Note 4) The minimum bending radius is the value measured as shown in the above figure ("How to measure the minimum bending radius").

- Use a tube above the recommended minimum bending radius.

- The tubing may be bent if used under the recommended minimum bending radius. Therefore, refer to the tube close bend radius and make sure that the tubing is not bent or flattened.

- The tube close bend radius is not guaranteed. The value of 2R is the value measured with a flattened tube using the method shown in the above figure ("How to measure the minimum bending radius").

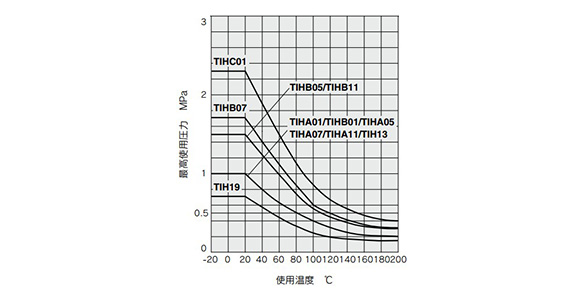

Inch Sizes TIH Series

Maximum operating pressure

Note) The maximum operating pressure varies depending on the inner diameter bore size even if the outer diameter is the same.

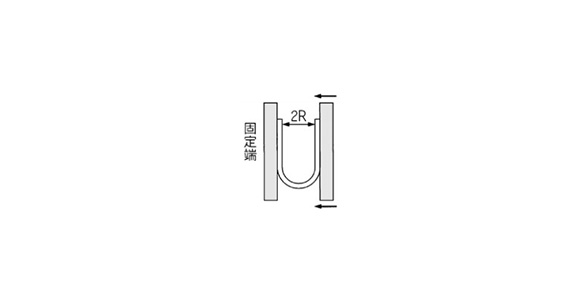

How to measure the minimum bending radius

Bend the tubing into a U shape at a temperature of 20°C. Fix one end and close the loop gradually. Measure 2R when the deformed ratio of the tubing diameter at bending reaches 5%.

| - | Inch Size | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal | TIHA01 | TIHB01 | TIHC01 | TIHA05 | TIHB05 | TIHA07 | TIHB07 | TIHA11 | TIHB11 | TIH13 | TIH19 | |

| Outer diameter | inch | 1/8 " | 3/16 " | 1/4 " | 3/8 " | 1/2 " | 3/4 " | |||||

| mm | 3.18 | 4.75 | 6.35 | 9.53 | 12.7 | 19.05 | ||||||

| Inner diameter | inch | 0.093 " | 0.086 " | 0.065 " | 0.137 " | 0.124 " (1/8 ") | 0.18 " | 0.156 " (5/32 ") | 0.275 " | 0.25 " (1/4 ") | 0.374 " (3/8 ") | 0.624 " (5/8 ") |

| mm | 2.36 | 2.18 | 1.65 | 3.48 | 3.15 | 4.57 | 3.95 | 6.99 | 6.33 | 9.5 | 15.85 | |

Specifications

| Fluid | Air, waterNote 1), inert gas | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicable fittingsNote 2) | One-touch fittings Insert fittings Fluoropolymer fittings: LQNote 3) Series | |||||||||||

| Maximum operating pressure (MPa) | 20°C | 1 | 2.3 | 1 | 1.5 | 1 | 1.7 | 1 | 1.5 | 1 | 0.7 | |

| 100°C | 0.4 | 0.85 | 0.4 | 0.55 | 0.4 | 0.6 | 0.4 | 0.55 | 0.4 | 0.25 | ||

| 200°C | 0.2 | 0.4 | 0.2 | 0.3 | 0.2 | 0.3 | 0.2 | 0.3 | 0.2 | 0.1 | ||

| Refer to the maximum operating pressure curve. | ||||||||||||

| Minimum bending radius mmNote 4) | Recommended radius | 25 | 20 | 10 | 35 | 25 | 55 | 35 | 85 | 60 | 95 | 220 |

| Tube close bend radius | 20 | 12 | 7 | 25 | 20 | 35 | 20 | 55 | 30 | 60 | 160 | |

| Operating temperature | Air, inert gas: -20 to 200°C / Water: 0 to 100°C (No freezing) | |||||||||||

| Material | FEP (Fluorinated Ethylene Propylene Resin) | |||||||||||

Note 1) When using a liquid fluid, the surge pressure must be under the maximum operating pressure. If the surge pressure exceeds the maximum operating pressure, it will result in damage to the fittings and tubing. Furthermore, abnormal temperature rise caused by adiabatic compression may result in the tubing bursting.

Note 2) Do not use in locations where the FEP tubing will move. Be sure to operate under the maximum operating pressure and maximum operating temperature conditions using the lower maximum operating specification of either the tubing or fittings. A material change over a long duration or due to high temperature may cause leakage. Perform periodic maintenance and replace with a new product immediately when abnormalities are detected. When the insert and miniature fittings are used over extended periods of time, it may cause leakage due to age-related material deterioration. In such a case, apply additional tightening to the tube connection part. If leakage still occurs after applying additional tightening, replace the fitting with a new product. For other precautions, refer to "Fittings & Tubing Precautions" in the catalog. When using the fluoropolymer fittings, refer to the precautions in the catalog. Select the size after confirming the outer diameter and inner diameter.

Note 3) TIHA01, TIHC01, TIHA05, TIHA07 and TIHA11 are not available because of different internal diameters.

Note 4) The minimum bending radius is the value measured as shown in the above figure ("How to measure the minimum bending radius").

- Use a tube above the recommended minimum bending radius.

- The tubing may be bent if used under the recommended minimum bending radius. Therefore, refer to the tube close bend radius and make sure that the tubing is not bent or flattened.

- The tube close bend radius is not guaranteed. The value of 2R is the value measured with a flattened tube using the method shown in the above figure ("How to measure the minimum bending radius").

Référence pièce

|

|---|

| TH1209R-20 |

| Référence pièce |

Prix unitaire standard

| Quantité minimale de commande | Remise sur volume | D.E. D (Ø) | D.E. [Distinction] | D.I. d (Ø) | D.I. [Distinction] | Couleur | Rayon de pliage minimum (mm) | Bundle winding length (m) | Applicable Tube Size | Pression de service maximum (MPa) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

706.35 € | 1 | 26 jours | 12 | Jusqu'à 15 | 9 | Jusqu'à 9 | [Transparent (y compris couleurs non blanches)] Transparence | 100 | 20 | Taille métrique | 1 |

Loading...

Informations de base

| Type | Droit | Utilisation du service de découpe | NA | Matériau | Résine fluorée |

|---|---|---|---|---|---|

| Fluide applicable | Eau / Air | Environnement de fonctionnement | Standard / Résistance à la chaleur / Résistance aux produits chimiques | Matériau, résine fluorée | Super PFA |

| Spécifications | Produit standard | Température de service(°C) | Air, gaz inerte : -20 à 200 / eau : 0 à 100 (ne pas laisser geler) |

Vous vous trouvez sur la page de Tube en fluoropolymère (FEP) gamme TH/TIH, le numéro d'article est le suivant: TH1209R-20.

Veuillez trouver plus de détails concernant les particularités et les dimensions sous le numéro d'article TH1209R-20.

Configurer

Propriétés de base

-

Type

- TH

- TIH

-

D.E. D(Ø)

-

D.E. [Distinction]

- Jusqu'à 4

- Jusqu'à 5

- Jusqu'à 6

- Jusqu'à 7

- Jusqu'à 8

- Jusqu'à 10

- Jusqu'à 15

- Jusqu'à 20

-

D.I. d(Ø)

-

D.I. [Distinction]

- Jusqu'à 2

- Jusqu'à 3

- Jusqu'à 4

- Jusqu'à 5

- Jusqu'à 6

- Jusqu'à 7

- Jusqu'à 8

- Jusqu'à 9

- Jusqu'à 10

- Jusqu'à 20

-

Couleur

- Blanc

- Transparent (y compris couleurs non blanches)

- Rouge

- Blanc

-

Bundle winding length(m)

-

Applicable Tube Size

- Taille en pouces

- Taille métrique

-

Pression de service maximum(MPa)

- 0.7

- 1

- 1.5

- 1.7

- 2.3

Filtrer par jours d'expédition standard

-

- Tous les articles

- Jour même

- 3 jours ou moins

- 4 jours ou moins

- 6 jours ou moins

- 7 jours ou moins

- 14 jours ou moins

- 26 jours ou moins

- 68 jours ou moins

- 98 jours ou moins

Propriétés optionnelles

- Les spécifications et les dimensions de certaines pièces peuvent ne pas être intégralement indiquées. Pour plus de détails, reportez-vous aux catalogues des fabricants .

Variantes de ce produit

| Référence pièce |

|---|

| TH0402N-20 |

| TH0402R-20 |

| TH0425B-20 |

| TH1210B-20 |

| TH1210BU-20 |

| TH1210N-100 |

| Référence pièce | Prix unitaire standard | Quantité minimale de commande | Remise sur volume | Jour d'expédition standard ? | D.E. D (Ø) | D.E. [Distinction] | D.I. d (Ø) | D.I. [Distinction] | Couleur | Rayon de pliage minimum (mm) | Bundle winding length (m) | Applicable Tube Size | Pression de service maximum (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

103.45 € | 1 | 4 jours | 4 | Jusqu'à 4 | 2 | Jusqu'à 2 | [Transparent (y compris couleurs non blanches)] Bleu (translucide) | 15 | 20 | Taille métrique | 2.3 | ||

147.13 € | 1 | 26 jours | 4 | Jusqu'à 4 | 2 | Jusqu'à 2 | [Transparent (y compris couleurs non blanches)] Transparence | 15 | 20 | Taille métrique | 2.3 | ||

140.61 € | 1 | 7 jours | 4 | Jusqu'à 4 | 2.5 | Jusqu'à 3 | [Blanc] Blanc (couleur du matériau) | 20 | 20 | Taille métrique | 1.7 | ||

514.31 € | 1 |

Jour même

Stock | 12 | Jusqu'à 15 | 10 | Jusqu'à 10 | [Blanc] Blanc (couleur du matériau) | - | 20 | Taille métrique | 0.7 | ||

484.84 € | 1 | 68 jours | 12 | Jusqu'à 15 | 10 | Jusqu'à 10 | [Rouge] Rouge | - | 20 | Taille métrique | 0.7 | ||

1,685.44 € | 1 | 68 jours | 12 | Jusqu'à 15 | 10 | Jusqu'à 10 | [Transparent (y compris couleurs non blanches)] Bleu (translucide) | - | 100 | Taille métrique | 0.7 |